Introduction

Ever picked up packaged food and noticed a little label saying Food Grade Certification? Most people don’t give it a second thought. But that tiny label is doing a big job; it’s protecting you.

In the food industry, packaging is more than just a wrapper. It’s the first line of defense between your food and the outside world. If the packaging isn’t safe, the food isn’t safe. That’s exactly why Food Grade Certification matters. It tells you the material touching your food won’t leak chemicals, change taste, or mess with quality.

Let’s break down what this certification means, why it matters, and why your food packaging should absolutely have it.

What is Food Grade Certification?

At its core, Food Grade Certification is proof. Proof that the packaging is safe for direct contact with food and drinks.

This means the material won’t:

- Leach harmful chemicals

- Change how the food tastes or smells

- Contaminate the food with toxins

The certification process involves rigorous tests on plastics, paper, foil, glass, metals, you name it. If it touches food, it gets tested.

Think of it as a seal of trust. Without it, you’re just guessing.

Why Food Grade Certification Matters in Food Packaging?

Food packaging has two jobs: keep food fresh and keep food safe. The second is non-negotiable. Here’s why Food Grade Certification is a must-have:

Heavy-duty foil rolls, on the other hand, are:

- Protects consumers: No nasty chemicals sneaking into your meal.

- Builds trust: Customers feel safer buying certified products.

- Keeps you compliant: Many countries demand certified packaging.

- Shields your reputation: Nobody wants to be in the news for unsafe packaging.

Certified packaging isn’t a nice-to-have. It’s essential.

Build Trust with Every Bite

We’re certified to ensure quality & safety

What Materials Need Food Grade Certification?

Pretty much all packaging materials. But some need it more than others:

- Plastic containers and bottles: Tested for BPA and chemical migration.

- Paper and cardboard: Checked for bleaches, inks, and coatings.

- Metals (aluminum, steel, tin): Certified to avoid food reactions.

- Glass jars and bottles: Naturally safe, but closures and lids still need testing.

- Foil trays and containers: Especially common in takeaways. Food-grade aluminum foil containers must always be certified.

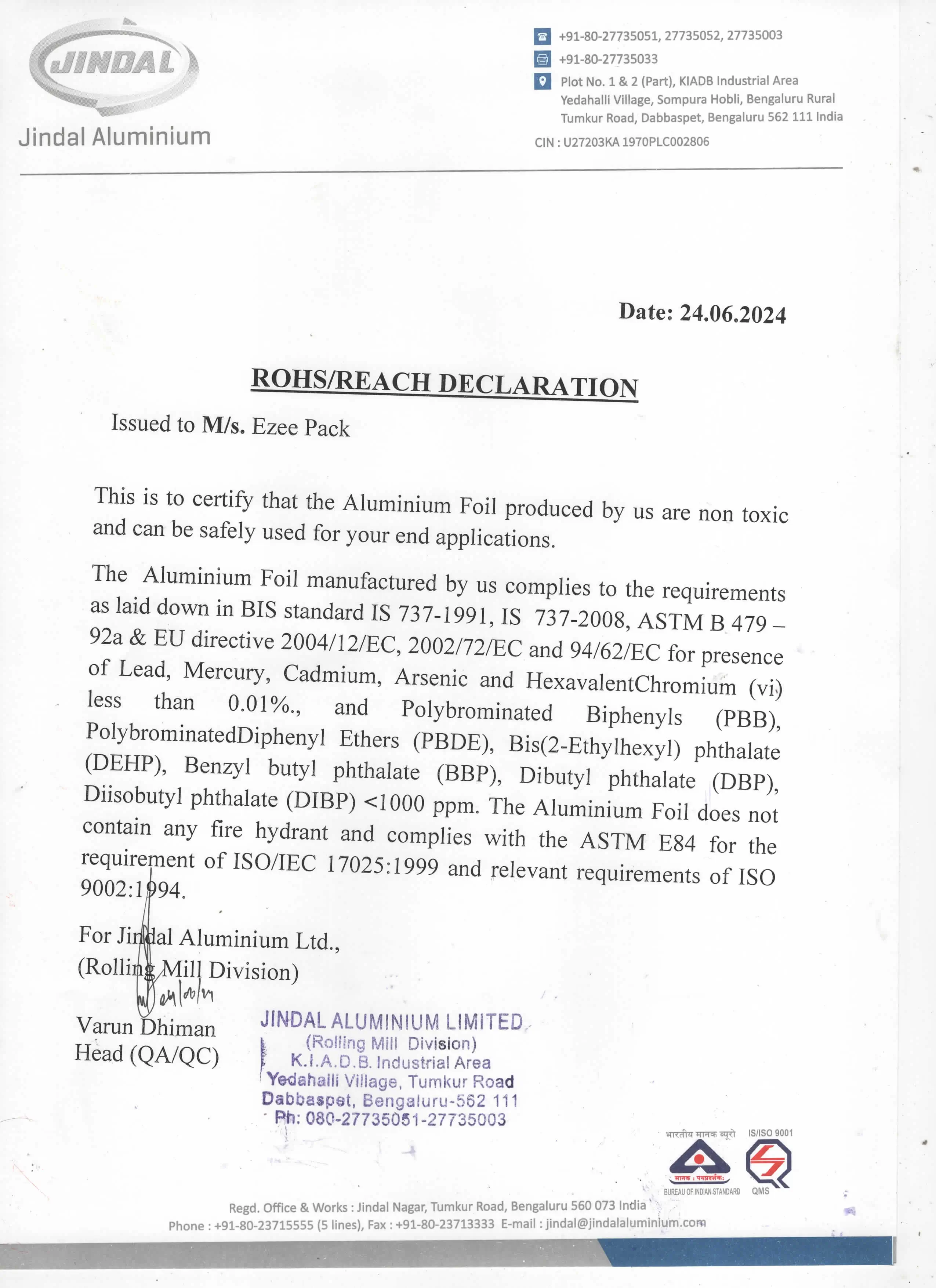

Global Standards for Food Grade Certification

Not every country plays by the same rulebook. Here are the big ones:

- FDA (U.S.): Rules on packaging, additives, and coatings.

- EU Standards (EC No. 1935/2004): Some of the strictest globally.

- BIS & FSSAI (India): Local regulators for packaging safety.

- ISO 22000: Broader food safety management, including packaging checks.

The rules may differ, but the goal is the same: safe food contact.

Why Should Your Food Packaging Have Food Grade Certification?

Here’s where the real business case comes in.

1. Protects Health: No one wants toxic substances sneaking into food. Certification means packaging is safe from the start.

2. Builds Brand Trust: Modern consumers are label readers. If they see “certified,” they trust you more.

3. Keeps You Out of Trouble: Unsafe packaging can land businesses with fines, lawsuits, or worse, a ecall.

4. Opens Export Doors: Want to sell in the U.S. or Europe? Without Food Grade Certification, your shipment will never clear customs.

5. Competitive Edge: When every brand is fighting for attention, “safe and certified” helps you stand out.

Misconceptions About Food Grade Certification

- “All packaging is food safe.” Nope. Only certified materials are tested.

- “Too expensive for small businesses.” Wrong. It costs less than a recall.

- “Looks safe, must be safe.” Looks are misleading. Certification is the only proof.

Real-World Examples

- Plastic bottle backlash: Brands once lost trust when BPA was found in bottles. Certification could’ve prevented it.

- Street food shift: Vendors in India now use food-grade aluminum containers instead of newspapers. It’s safer and looks professional.

- Export rejections: Many exporters lose money when shipments fail packaging checks. Certified packaging solves this problem.

How Businesses Can Ensure Packaging is Certified?

Want your packaging to pass the test? Do this:

- 1. Source from certified suppliers: Always ask for proof.

- 2. Get independent testing: Accredited labs confirm safety.

- 3. Keep records: Certificates and compliance papers matter during audits.

- 4. Train teams: Your staff should know what to look for.

- 5. Stay updated: Regulations change, so stay in the loop.

The Future of Food Packaging and Certification

Packaging is changing. It’s no longer just plastic wraps and cardboard boxes.

- Biodegradable plastics: Eco-friendly, but still need certification.

- Reusable containers: Must be tested for durability and safety.

- Smart packaging: Tech-driven solutions that still need food safety approval.

Trends may change. Certification won’t.

Conclusion

The brutal truth is that food-grade certification isn’t optional. It’s a guarantee. A promise that your food packaging is safe, compliant, and trustworthy. From food-grade aluminum containers to plastic bottles, certified packaging keeps food pure and brands protected.

If you’re in the food business, certification is your shield. It protects your customers, your reputation, and your growth. Invest in it, because food safety isn’t a trend. It’s the foundation of trust.

Enjoyed this fresh perspective? Want to bring behavioral insights into your product, brand, or kitchen?

Get in touch here